LABC has a suite of 360 registered construction details (RCDs) to help you combat the problem of cold bridging in construction that will minimise heat loss through the weak junction points in a building’s outer envelope.

“Construction joints” are those parts of a building where different elements meet and are joined together.These are the focus of attention because research has shown they create thermal bridging, which allows heat to leak out and can also create cold spots internally. This can be at the edge of a ground floor where it touches an exposed wall or an external wall where it runs into a roof, lintel or sill to a window or door jamb.

The SAP assessment calculation that is used to prove compliance with Part L of the Building Regulations has 42 different junctions that must be detailed. LABC RCDs now provide for the first time a combination of different materials and products that can be used together and provide certainty as to compliance with Part L of the Building Regulations.

Key benefits of using LABC RCDs:

- Reduction in thermal bridging

By using one of our specified details, it is now possible to demonstrate that a building which would have previously failed to comply with Part L can pass with no alteration to insulation levels or the need to use triple glazing or expensive renewable technologies.

Cost analysis has shown savings as much as £1,200 on a 90m2 unit are possible when using an LABC RCD.

- Free expert guidance on tap

LABC RCDs are available free of charge on the LABC website. These details can also be accessed from your mobile phone or other smart tablet.

LABC RCDs presently encompass masonry construction and over time will be extended to include timber frame, light steel frame, external wall insulation among others. Find out more by visiting http://www.labc.co.uk/labc-registered/construction-details

E5 Ground Floor Junction with an External Wall E5MCPF16

This junction can account for up to 34% of heat loss through thermal bridging so it is important to ensure the materials specified in the detail are used and positioned exactly as detailed. Attention to detail will ensure you meet Part L of the Building Regulations. There are 66 different construction details you can use in this situation, each one having unique Psi values provided by the material manufacturer to ensure compliance when using SAP software. As a result, not only is it important to position the materials exactly as the Detail but it is crucial that the specified materials are used (even if they are not in stock at the builder’s merchant).

The registration number tells us it is detail number E5, that masonry has been used and the cavity has partial fill insulation.

So to ensure your detail does achieve compliance:

- Make sure your mortar joints finish flush for internal wall surfaces - this will ensure the floor insulation can sit tightly against the blockwork.

- Use a full sheet of insulation around the perimeter and position any offcuts in the centre of the floor.

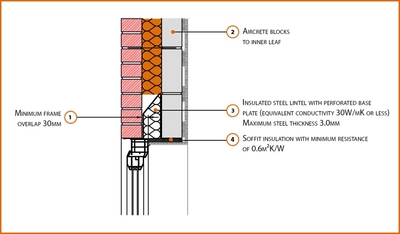

E1 Steel lintel with perforated steel base plate E1MCFF2

This junction can account for up to 26% of heat loss through thermal bridging, so it is critical the metal lintel is isolated from the external wall to minimise heat loss through the structure.

In this detail the registration number tells us it is detail number E1, that masonry has been used and the cavity has full fill insulation.

Key construction points are:

- Check the lintel is capable of spanning the required opening.

- Insulation generally has to be positioned inside, outside and beneath the lintel to ensure it performs adequately under Part L.

- Ensure all insulation is in position before fixing plasterboard.

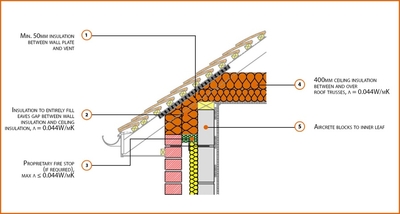

E10 Eaves (insulation at ceiling level) E10MCPF4

This junction can account for up to 11% of heat loss through thermal bridging and is a major cause of the growth of mould at the junction between wall and ceiling.

In this detail the registration number tells us it is detail number E10, that masonry has been used and the cavity has partial fill insulation.

Key areas to consider are:

- Pitch of the roof which, if shallow, can prevent full thickness of insulation being installed at the roof/wall junction. It is important to fill this void and ensure insulation is continuous with the wall insulation; flexible insulation can be dressed down into the cavity to achieve this.

- Ensure any eaves ventilation is not blocked or compressed and so preventing adequate ventilation of the roof.

- Where there is a habitable room in the roof space ensure the insulation is continuous.

- Party wall junctions and ceiling detail where they abut an adjoining external gable wall.